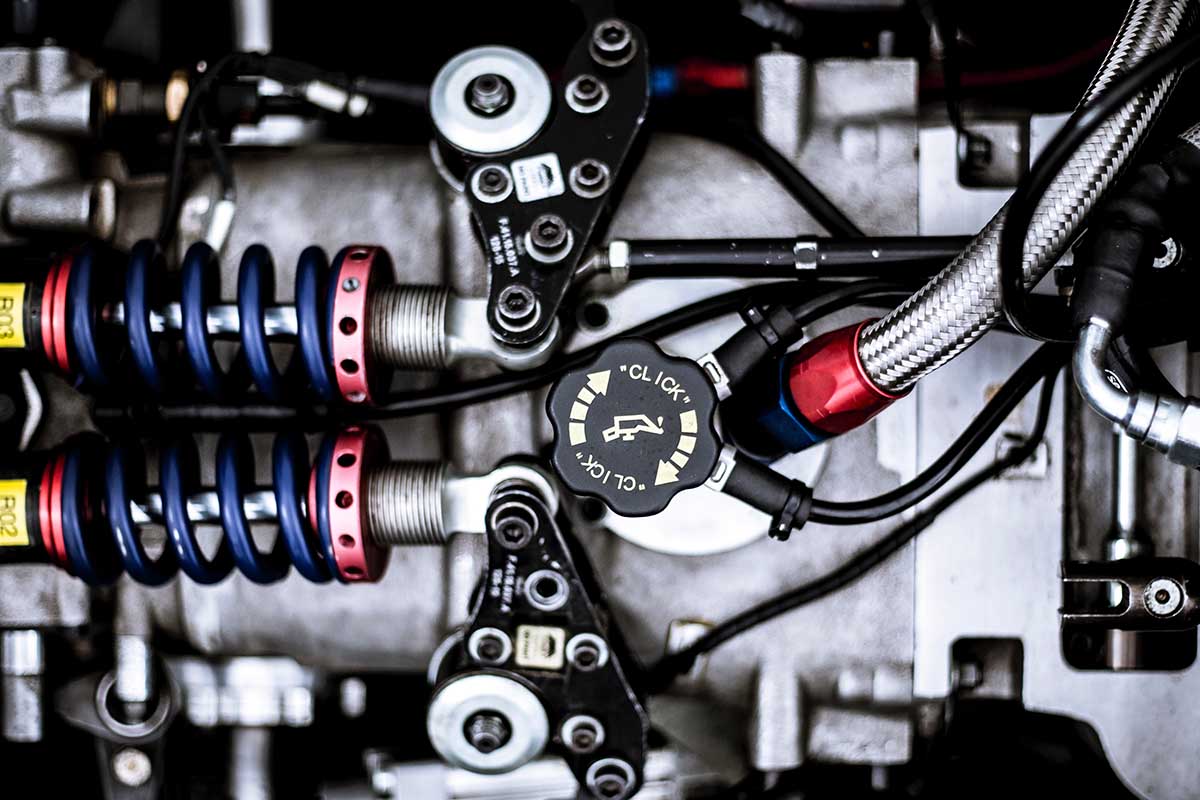

Different Components of a Pneumatic System

A pneumatic system assembly ranges from a simple air-driven piston configuration to multiple complex actuators used in mining applications. Every pneumatic system uses compressed air as a power source, which then moves to the actuators to produce mechanical motion.

Since atmospheric air is abundant and cheap, it is what pneumatic systems typically use. In some cases, atomized air may be added to compressed air, making it easier to pass through mechanical parts.

In most industrial applications, a pneumatic system is preferable over hydraulics because it produces less noise, is easier to use, and cheaper. To understand the function of a pneumatic system, here is a breakdown of the different parts and components that make up a standard pneumatic assembly.

Compressor

The compressor used in pneumatic systems is an electric or gas-powered pump. This pump will compress the air so that it reaches a higher PSI. Depending on the configuration, the compressor may include a holding tank for the air where it is stored before getting released into the track.

Check valve

A pneumatic check valve is one-way, and it is attached to the hose which connects the compressor to the buffer tank. The function of the check valve is to allow air to accumulate in the buffer tank but prevent backflow.

Gauges and regulators

These instruments are either attached to the compressor tank or directly on the compressor. A regulator functions either electrically or mechanically and triggers the air released into the track. On the other hand, gauges provide the operator with information on how to regulate the air pressure inside the compressor.

Accumulator or buffer tank

The compressor is the main holding area for air, while the buffer tank serves as secondary storage. Air stored in the buffer tank is ready for use anytime it is needed. The purpose of a buffer tank is to prevent air from flowing irregularly in the actuator.

components of a pneumatic system: Feedline

A feed line is a hose that moves or transfers compressed air through the system. In choosing a feed line, it is best to use the most extensive available hose diameter, which is capable of handling the air pressure. More massive feed lines allow for smooth movement of pressurized air into the system and also prevent backups in airflow.

Directional valve

A directional valve is installed before the pneumatic actuator. If the application requires multiple actuators, the system will also need various directional valves. A directional valve can receive power from an electric or mechanical source. These valves stop, re-direct, and release pressurized air into the actuators as desired. The operator uses a button, lever, or some device to trigger these valves.

Pneumatic actuators

The most important part of a pneumatic system is the actuator. This part is where all the work happens. Actuators also come in a variety of configurations. Standard pneumatic assemblies typically use either a cylinder or plunger actuator.

Pressurized air coming from the tank or compressor gets released into the system and moves the piston as air travels through the pneumatic chamber. A typical example of a pneumatic application is air-powered construction tools and dentistry equipment.