Scaffolding 101: Best Reasons for Using Them in Construction

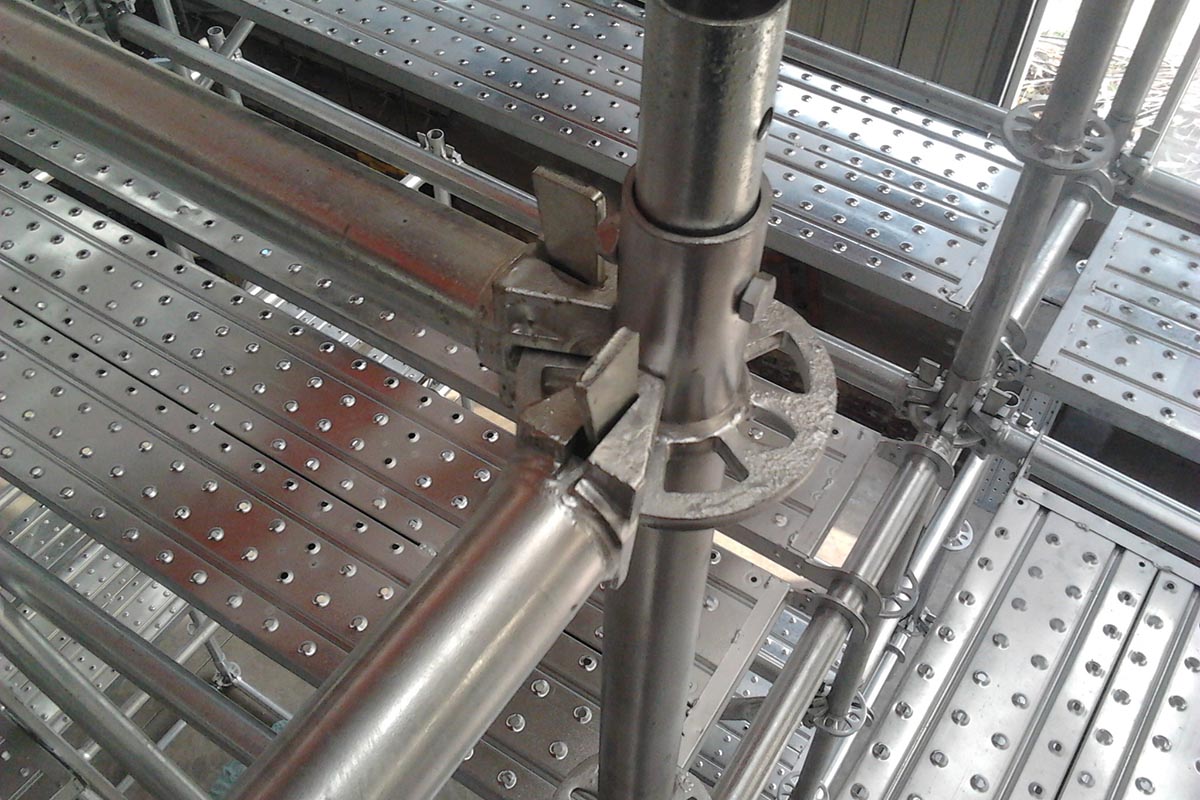

Whenever you see construction going on, you would most certainly see rods constructed together and workers walking over them and bringing construction supplies.

The mere fact that it is used as a pathway for people to do their job so that they can complete the construction is a good reason why it should be maintained and made of suitable quality materials.

If you are in search of scaffolding for hire, there are some points that you need to remember.

Where to keep the scaffolding

There are manufacturer rules that you need to be aware of when installing the scaffold.

They need to be kept in a damp-free, frost-free location, especially if the materials that the scaffolding is made of are easily prone to rust.

When the scaffolding is your responsibility while the construction is in progress, you have to be aware of the different scaffolding equipment and where they are supposed to go.

You can then determine the best possible way to care for the scaffolding.

What are they made of?

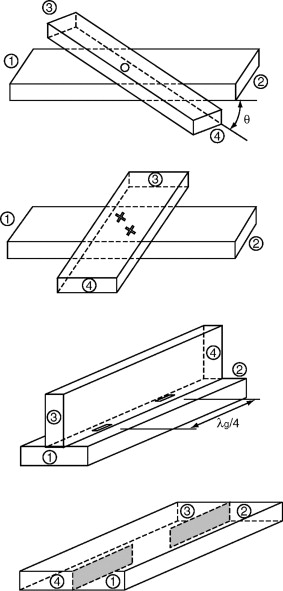

For erected scaffolding, they are made of tubes, couplers, and boards. There is the lightweight tube scaffolding that was the standard type for decades.

For pipes, they are made of steel or aluminum, but some examples make use of filament-wound tubes in a nylon or polyester matrix.

The boards make for an excellent work surface, and they are made out of seasoned wood that ranges from 38, 50, and 63 mm.

Their lengths may also vary from 225 mm and a maximum of 3.9 m long.

Couplers are fittings that keep the tubes together. The most popular are the scaffold couplers with types such as the right-angle, putlog, and swivel couplers.

Are there standards to watch out for?

For specific issues, the DIN 4420, which is split up into five parts where the designs of scaffolds, safety requirements, and standards are listed.

There is also a list of material, dimensions, components, and load-bearing standard capacity that you can look at if you need it.

DIN 4421 lists the analysis, design, and falsework construction. Falsework is made up of temporary structures that support a permanent installation until it can sustain itself.

Ensure that you are aware of these standards if in case you will require scaffolding for hire.

Types

Joint-tube scaffolding is easily customizable, because of the tube conjunctions in every known position to any needed distance.

Adjusting the temporary structure is easy as joint-type scaffoldings allow for every type of facade or project. It is suitable for renovations, construction, and performance work.

For prefab frame stationary scaffoldings, it is the most used type by non-specialized companies.

There are shorter processing times and more affordable costs on non-specialized personnel that make this scaffolding one of the best options.

Omnidirectional scaffolding

It pairs the versatility of joint-tube scaffolding and the simplicity of prefab frames.

It is known throughout Europe and has only penetrated the Italian market just recently.

You do not want to have any professional help to put up the scaffolding because it only uses regular ties to set it up.

Construction Scaffolding: Mast climbing work platform

Do you have any construction work to be done on high buildings?

This type of scaffolding does not need to worry about barriers of different sizes and can be constructed without an additional cost.

Despite its adaptability to high buildings, it does not require a lot of time to get it set up.