5 Industries that Benefit From Injection Mold Technology

Injecting mold technology is used by multiple industries these days, which was further boosted by the pandemic thanks to rising demands. Products produced using this process became much sought after due to safety concerns and the recovery measures put in place. There is also the fact that multiple industries sprang up that made liberal use of said products to grow themselves. As a result, injection mold manufacturing became a behemoth that is expected to get even bigger in the future.

Knowing which industries benefit from the growth of injection mold technology is important from a business standpoint due to opportunities. Right now, there is a chance for enterprising minds to ride the waves that the process is kicking up. This could then lead to great profits when you are able to position yourself in a way that benefits you. The ones that will be covered here are only a few on a growing list, as well.

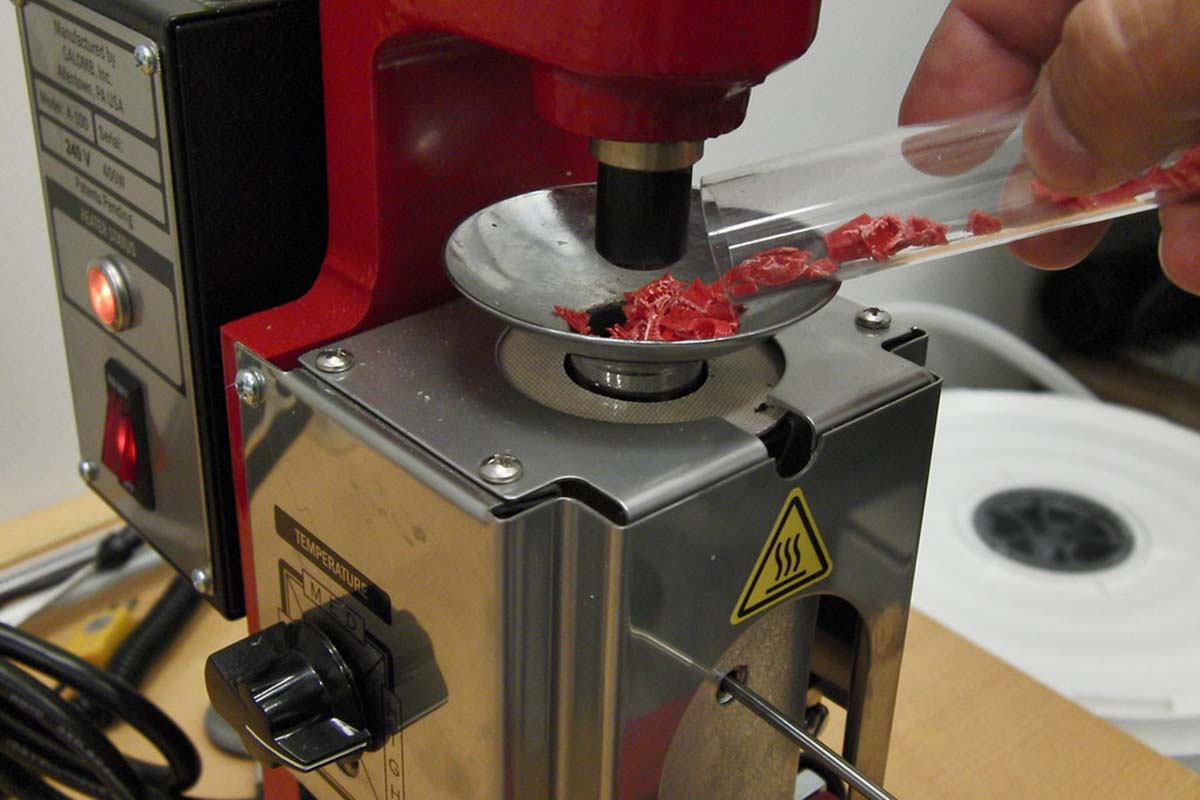

Medicine

Due to the rise of the pandemic, the medical industry scrambled to contain the situation through various means and potential solutions. One of the measures taken to ensure public safety is the increased use of packaging materials such as lids and containers. Many of these are produced using injection mold manufacturing and rely quite a bit on quality control. It’s worth noting that the recent strides in curbing the rise in infection rates are due to these products.

There is also the matter of the medical contraptions, machines, surgical arms, and various packaging solutions that came up. The scarcity of ventilators, for example, was one of the most pressing issues that came up in the beginning. Due to the production of the necessary parts to make those machines, the problem was addressed in due time. A lot of this is also because of how efficient injection mold manufacturing can be.

Food and Beverage

Another industry that is now more reliant on the products produced via injection mold technology is the food and beverage sector. This comes in the form of containers, packaging, marketing, utensils, and so much more. The current pandemic has resulted in a rise in demand for all of those items and more at staggering rates. The industry was already making use of them before, but now, there is no denying the dependency between them.

The booming market that is food delivery services is fueling this rise in unexpected ways, as well. With customers getting used to having any type of food they want delivered to their homes, this won’t slow down. In the coming years, it’s expected that fewer and fewer customers will be going to actual restaurants to eat. Instead, they will be more likely to order the fishes that they want to their homes or their place of work.

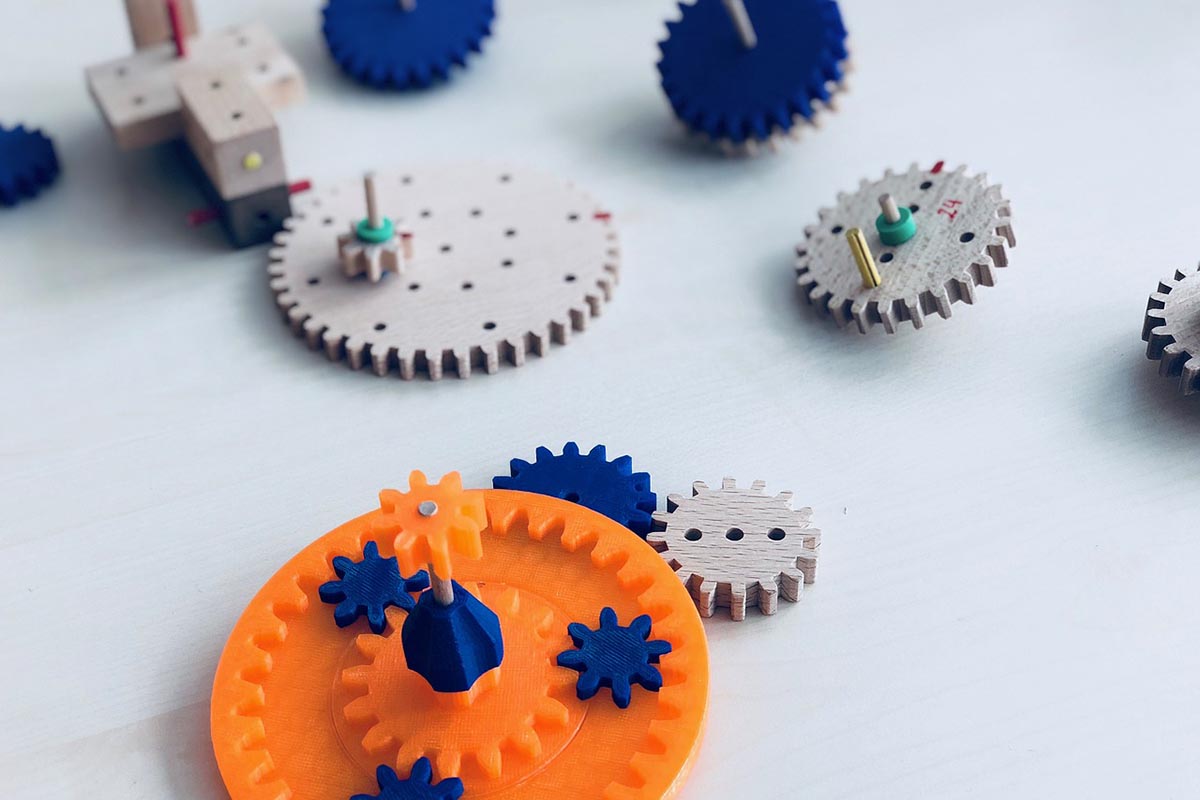

Manufacturing

The field of manufacturing makes use of cogs, gears, casings, shunts, and so many more in order to work. Many of these are produced using injection mold manufacturing technology so that they can produce strong parts for less cost. They are lightweight, versatile, precision-molded, and are also made to be durable enough to get the job done as needed. Gears made using this process are also known for their efficiency in terms of transferring energy and resisting friction wear.

The methods used by manufacturers benefit from injection mold technology, as well, in the form of casings, extra layers, and more. Then there are the molds that are used during the manufacturing or production process for things like food or toys. This explains the popularity of manufacturing via injection mold in China and other major production sectors all over the world. Injection mold manufacturing itself has also contributed to the increase in the quality of goods coming out of these sectors.

Robotics

Despite the reputation that robots might have earned, there are many examples of them being made of plastic parts. A good example of this would be robot vacuums, which are made of lightweight but durable polymer casings and components. Injection mold technology is used to create these and many other items, which then allow robots to function. This applies to everything from mass consumer products to high-end, industry-grade manufacturing robots that require more robust parts.

The same goes for things like accessories, camera components, artificial limbs, and many more that are part of the robotics field. With how well this manufacturing process can produce products with unrivaled efficiency and precision, this trend is expected to continue. Another point of interest with regard to injection mold technology and robotics is the issue of drones and their popularity.

Auto Industry

Last but not least, the auto industry has been a recipient of parts from injection mold technology for many years. Some of the most essential components of cars, trucks, and even motorcycles are now made using this technology. There is also the point about accessories, gadgets, and other auto additions for adding more features to the vehicle. Many of these are made using this manufacturing process to great effect.

At this point, the vast majority of modern vehicles are using components that came out of an injection mold assembly line. This is due to the quality of the products produced and the precision that the process is known for. Accuracy leads to much better results when dealing with a machine that is as complex as a car, after all. Every single part needs to work as intended or risk disaster.

Injection Mold Technology: Conclusion

Numerous industries have benefited from injection mold technology and what it can produce. It would be safe to say that a huge chunk of today’s businesses uses products made using this process. Some of these businesses are worth more than others, but the fact remains that they rely on injection molding technology.