The Manufacturing Process of RF Coils

Among various applications in several industries, RF coils or Radio-frequency coils are mainly used in the preparation of MRI machines. In MRI machines, RF coils play the role of transmitters and receivers. This article will help you understand the characteristics and manufacturing process of RF coils.

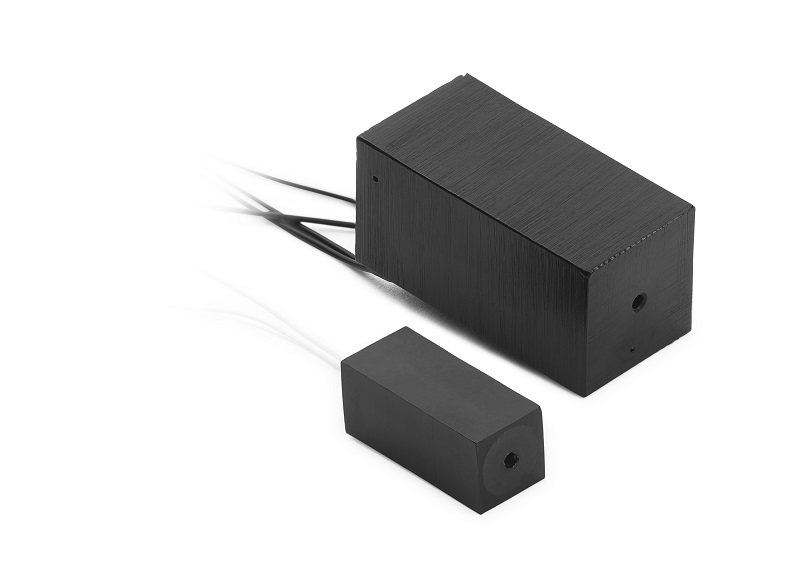

Description of the RF Coils

RF coils have the following characteristics.

- RF coils include the winding process of insulated wire around a core. This conductive wire helps in the generation of a magnetic field. However, the coil helps to strengthen the magnetic field significantly;

- The magnetic field that is developed around the core has a quite similar shape as a bar magnet. It also has a north and south pole. However, based on the requirements, manufacturers can also provide different shapes for the coils;

- The strength of the magnetic field increases with the addition of layers in the winding process of the coils.

Application of RF Coils

In several applications and industries, including electronics and medicine, RF coils have significant usages. To prepare the Magnetic Resonance Imaging or MRI machines, RF coils are essentials. RF coils function as receivers and transmitters in MRI machines.

Manufacturing Process

The manufacturing process of RF coils involves four essential steps such as:

- The first step involves the designing of the coils. The coils’ primary design is crucial for the preparation of the coils for MRI machines, and it requires modeling and simulation tools. COMSOL Multiphysics is a popular tool for the deigning of the coils. The required space for procyclic winding can be achieved through an interactive approach. Thus, a manufacturer must carefully calculate the cross-section of the insulated wire, necessary numbers of winding, and the highest available space for an insulated core.

- In the second step, manufacturers require to determine the type of core. Based on the controlling frequency of the device, one needs to decide the material for the core. To determine the suitable kind of core for the preparation of the coils, manufacturers should consider several factors. For instance, in some cases, one can choose ferrite cores or powdered iron cores.

- The third step is the most important, and it involves the winding of the coils. In the winding process, a conductive wire gets wound around a core after insulation. Depending on the required inductance and other characteristics of the core material, manufacturers decide upon the number of turns. Inductance increases with the increase in the number of turns. Industrial manufacturing of this modern world involves automated machinery for the winding of the coils. However, for the production of RF coils, the procyclic winding method is the most effective process. In this method, the upper layer of the wire takes place in the grooves of the lower layer of the wire. This method provides an outstanding fill factor as you can include most wires for a given volume. The quality of the copper material and the coating also significantly affect the winding process of RF coils.

- Finally, you can get the finished product of RF coils after testing and validation.