Coordinate Measuring Machines: All You Need To Know

In the manufacturing world of prototypes and components for all types of products, the parts’ geometric characteristics and dimensions are a crucial part of the equation. Manufacturing errors due to wrongfully measured dimensions or incorrect geometries can jeopardize the entire production process. Enter coordinate measuring machines, invented to withstand high tolerance measuring for manufacturing purposes.

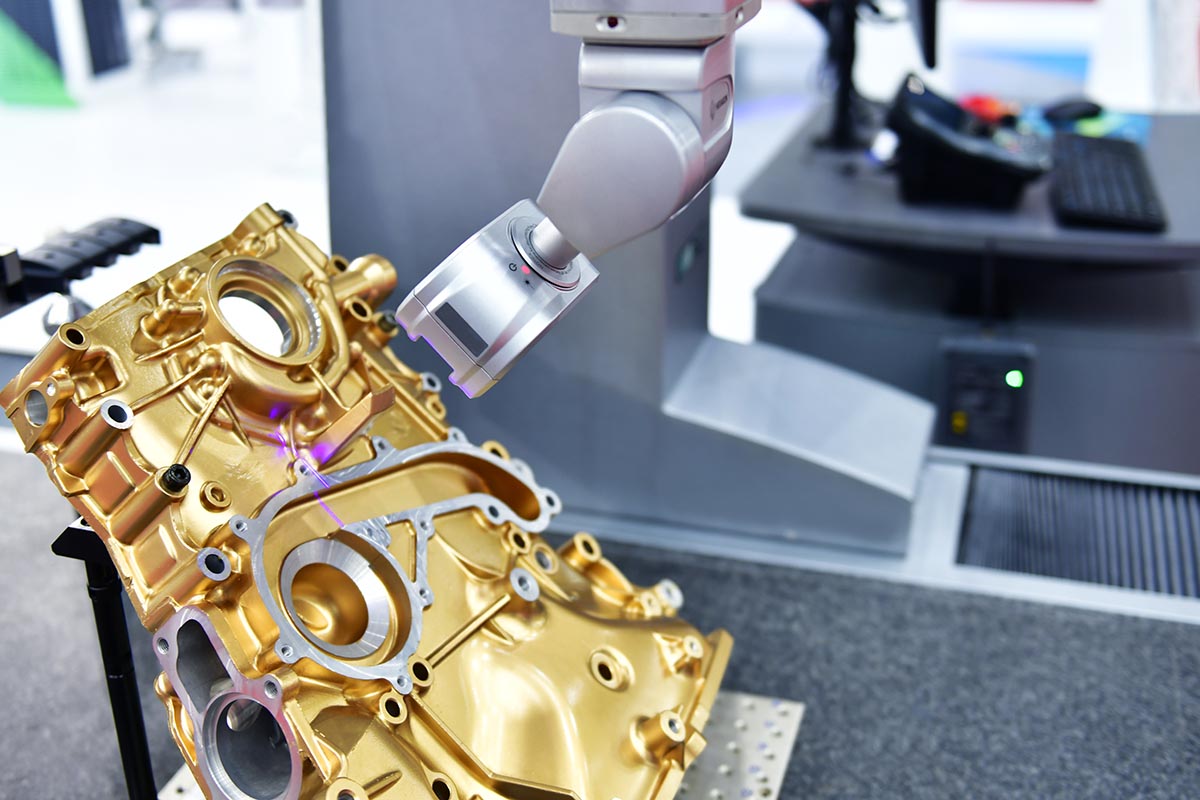

Photo from Metrology News

Since their inception up until now, coordinate measuring machines have played a significant role in each manufacturing process. In this brief article, we’ll explain what CMM machines are and provide answers to the questions like how they work, what they are used for, and cover the main benefits these machines provide manufacturers worldwide. So, without further ado, here’s everything that you should know about coordinate measuring machines.

What Is A Coordinate Measuring Machine?

As we already mentioned, each manufacturing process requires knowing the produced parts’ accurate geometric and physical dimensions. Well, there are two primary methods that people use for this purpose. The first one is the conventional method that involves the use of hand-measuring tools or optical comparators. Nevertheless, these tools require a certain level of expertise on account of the professional conducting the measuring process and are prone to errors.

The other, more sophisticated method for measuring parts in manufacturing involves utilizing coordinate measuring machines to get the job done error-free. These machines, or tools, can precisely measure the dimensions of each piece thanks to the unique coordinate technology that is essentially the principal component of the measuring equipment. In other words, a CMM machine is a sophisticated device that utilizes a probe mounted to the machine’s third moving axis to define the exact measurements of the part in question.

How Does It Work?

The whole measuring process begins by placing the part or component on the coordinate measuring machine base, where the measurement actually takes place. The base plate is made from a dense material that provides rigidness and stability, ensuring that external processes or forces won’t disrupt the measurement.

Right above the base plate, there’s a mounted movable gantry suspending a vertical column equipped with the measuring probe. The machine itself can move the probe along the X, Y, and Z-axis, digitally replicating each facet of the manufactured piece. When the probe strikes the object, the stylus creates an electrical puls that’s mapped out by computer software. Contingent on the size of the manufactured part, this process is sometimes repeated to gather thousands of measuring points.

Photo from 3ERP

Why You Might Need A Coordinate Measuring Machine?

Right after answering the questions of what a CMM machine is and how they work, we should also cover why they are so relevant to each manufacturing process. Answering this question comes with understanding the disparity between traditional and new manufacturing operations methods.

While the traditional method of measuring parts has many limitations and can lead to the supply of parts that are not good enough, the coordinate measuring machines have the speed and accuracy to repeatably measure parts in a superior fashion compared to the traditional methods.

CMMs also increase the productivity of manufacturing sites while reducing the tendency of making errors in the measuring process. Put differently, these machines can save you time and money and improve your manufacturing company’s image and reputation.

Top Benefits Of CMMs For Manufacturing Companies

Below, we’ll go through the biggest benefits of using coordinate measuring machines in your production workflow.

Quality Assurance Is Guaranteed

Unlike the traditional method of measuring parts and components’ dimensions, the coordinate measuring machine is way more reliable. CMMs digitally analyze and measure the parts while providing other services like CAD comparison, dimensional analysis, tool certifications, and reverse engineering. All these processes guarantee quality assurance and top-level products.

CMMs Can Save You A Lot Of Money And Precious Time

Nowadays, CMMs are integral to the production flow of each serious manufacturing facility because of their accuracy and speed. As the production of complex parts is becoming rampant in today’s manufacturing sector, the CMM is ideal for measuring their dimensions quickly and efficiently. Ultimately, the coordinate measuring process can save you a lot of time and money.

Less Human Involvement

Each coordinate measuring machine is a computer-controlled machine and consequently reduces the need for the involvement of human personnel in the component measuring processes. Besides being cost-efficient since they can work independently, CMMs also reduce operational mistakes that lead to further manufacturing problems.

Final Thoughts

Ensuring that the final manufactured part is identical to the digital design is essential because even minor defects or flaws in its structure can cause your production to fail. For that reason, if possible, you should always use a coordinate measuring machine to acquire the most accurate measurements of your developing products possible.