A Complete Guide to Improving Your Productivity Technology Within Your Manufacturing Plant

Technology has come a long way in the manufacturing industry. Today, there are countless ways to improve productivity within your plant.

The options are endless, and with the correct work instructions designed specifically to improve operations in the factory and the field, you can utilise advanced software programs that help you track inventory and production right through to sophisticated machinery that speeds up the manufacturing process.

This guide will discuss the most effective methods for improving productivity using technology.

We’ll also provide tips on how to choose the right tools for your business and how to implement them effectively. Let’s get started!

Implement an inventory management system

If you’re still relying on paper-based inventory management, it’s time to switch to a digital system.

An inventory management system will help you keep track of your raw materials, finished products, and work-in-progress.

This way, you can avoid production delays due to stock shortages.

Additionally, you’ll be able to see exactly how much inventory you have on hand at any given time, so you can better forecast future needs.

Also, consider using a barcoding system to streamline your inventory management further.

Use machines and equipment that are designed for productivity

Investing in production machinery is one of the most important investments you can make in your manufacturing business.

If your machines are outdated or not designed for efficiency, it’s time for an upgrade.

Look for automated or semi-automated machines – this will help reduce the need for manual labor and increase production speeds.

Additionally, make sure your machines are well-maintained and regularly serviced.

Tools like oscilloscopes can be invaluable for this purpose, as they help monitor and diagnose the electrical performance of your machinery, ensuring smooth operation and identifying potential issues before they lead to costly downtime.

Think about rugged embedded computing solutions

Rugged embedded computing solutions from Rigel Engineering are ideal for manufacturing plants.

They are designed to withstand harsh environments and can help you improve productivity in a number of ways.

For example, rugged computers can be used to track production data in real time so that you can identify areas of improvement.

Additionally, they can be used to control machinery remotely or monitor workplace safety conditions.

If you’re looking for ways to increase productivity and efficiency in your manufacturing plant, investing in rugged embedded computing is a smart move.

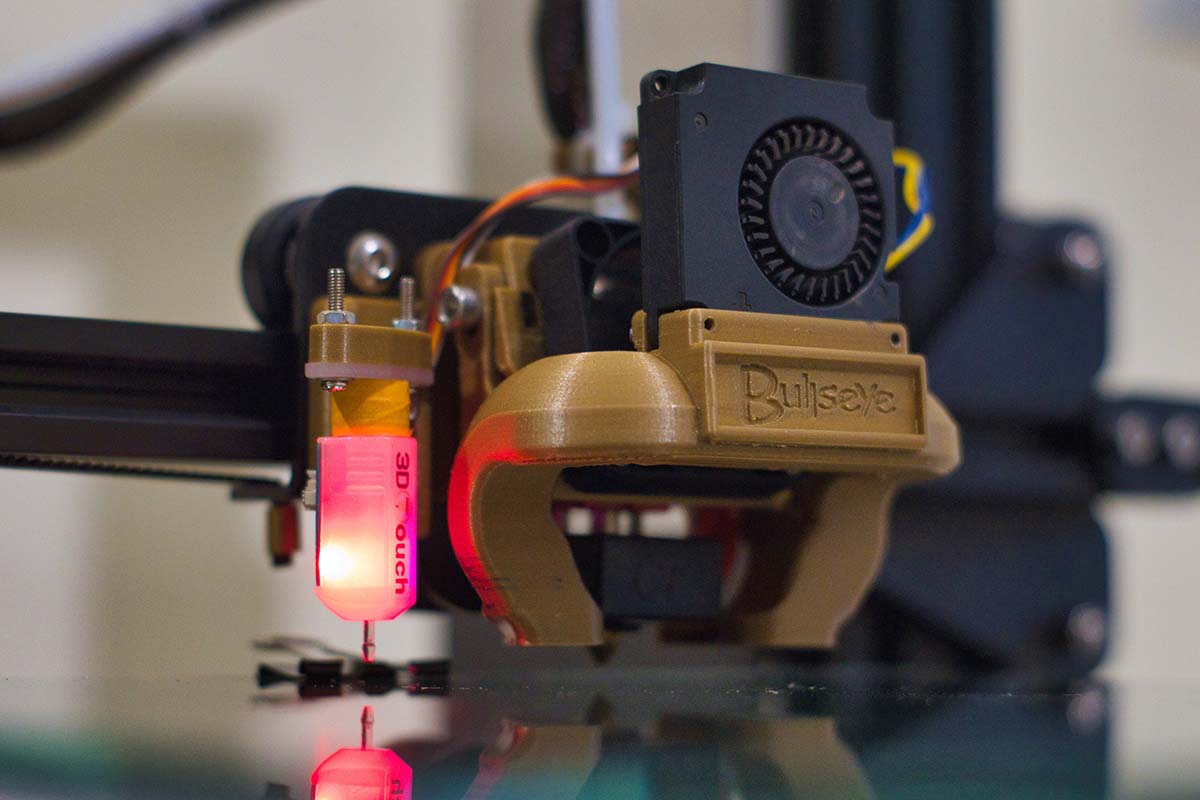

Introduce 3D printing technology

3D printing is another technology that is revolutionizing the manufacturing industry.

With 3D printing, you can create prototypes quickly and easily without needing expensive tooling.

This can help you save time and money during the product development process. Additionally, 3D printing can be used to create custom parts and components – which can be particularly helpful if manufacturing small batches of products. Now is the time to start if you’re not already using 3D printing in your manufacturing business.

Productivity technology within manufacturing plant: implement an advanced software system

An advanced software system can do wonders for a manufacturing business.

The right software program will help you track inventory levels, production data, and employee productivity.

Additionally, it can help you streamline your supply chain, getting raw materials and finished products to market faster.

When choosing a software system for your business, make sure it is scalable and user-friendly. Also, be sure to get expert help with the implementation process to ensure that everything goes smoothly.

There are many ways to improve productivity in a manufacturing business – it just takes some creativity and out-of-the-box thinking.

However, by implementing the tips and tricks discussed in this guide, you can take your business to the next level.