Manufacturing companies must constantly review and assess their supply chain management processes to remain competitive in the global market. Ensuring a well-run supply chain strategy can help reduce costs, improve quality, enhance customer satisfaction, and optimize productivity – all critical components of a successful business operation.

In this post, expert Christopher Linton in Houston, Texas, will outline the primary approaches used by industry leaders to overcome common manufacturing supply chain challenges and provide guidance on how manufacturers can leverage these strategies to maximize efficiency while minimizing cost.

Introducing Supply Chain Management into the Manufacturing Process

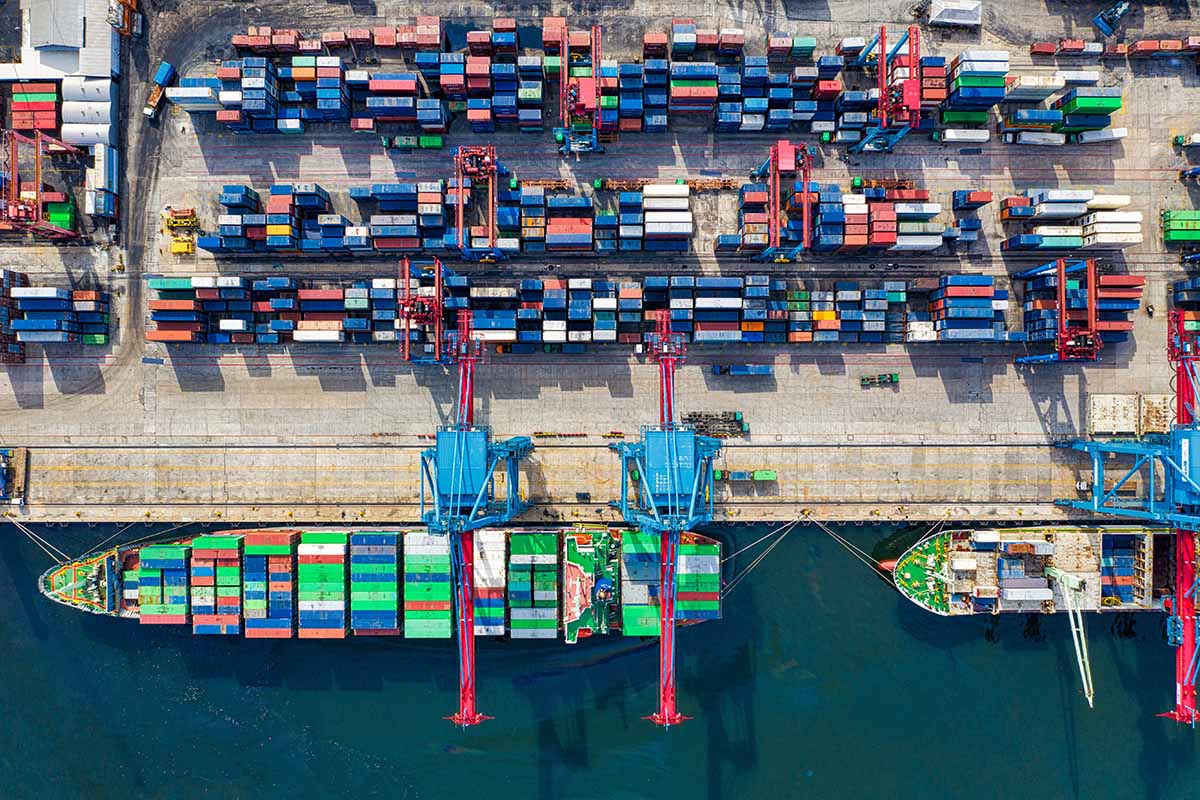

As the manufacturing industry continues to evolve, there is an increasing emphasis on integrating supply chain management. This approach involves looking beyond traditional manufacturing methods and considering the entire supply chain from beginning to end. By adopting this approach, manufacturers can optimize their operations to achieve greater efficiency, reduce costs, and ensure a steady supply of high-quality materials.

However, implementing supply chain management in manufacturing requires careful planning and execution. It involves collaboration with suppliers, logistics providers, and other key stakeholders to create a seamless system that delivers products on time and at the desired level of quality. With the potential benefits far outweighing the challenges, it’s clear that supply chain management is a vital tool for any manufacturer looking to remain competitive in the modern economy.

Benefits of Supply Chain Management for Manufacturers

Christopher Linton says supply chain management can benefit manufacturers looking to optimize their operations. By managing the flow of goods and services from suppliers to the end customer, manufacturers can reduce costs, increase efficiency, and improve customer satisfaction.

Supply chain management also allows for greater visibility and control, which enables manufacturers to react quickly to any disruptions or changes in demand. The ability to forecast the market will enable manufacturers to maintain sufficient inventory levels to meet customer needs while minimizing the costs associated with excess inventory.

Supply chain management can help manufacturers identify areas to reduce waste, improve sustainability, and enhance corporate social responsibility. Ultimately, supply chain management is essential for manufacturers looking to improve their bottom line and remain competitive in today’s global marketplace.

Strategies to Implement Supply Chain Management in Manufacturing

The integration of supply chain management in the manufacturing industry is a crucial factor that can lead to growth and success. Organizations implementing effective supply chain strategies can optimize operations, reduce costs, and enhance customer satisfaction. One key system is establishing collaborative relationships with suppliers and distributors.

This approach encourages active communication to ensure everyone is on the same page and working towards a common goal. Another effective strategy is to invest in technology and automation. This can help streamline production, reduce waste, and improve efficiency. Lastly, creating a culture of continuous improvement is crucial. Encouraging staff to identify and address inefficiencies in the supply chain can lead to long-term sustainability and growth. Implementing these strategies can lead to greater flexibility, reduced lead times, and increased profits.

Utilizing Technology to Improve Efficiency and Accuracy in the Production Line

Christopher Linton says technology has revolutionized how we work and communicate and has done wonders for manufacturing. Technological advances make production lines more innovative and efficient, allowing companies to keep up with increasing demand without sacrificing quality. Manufacturers can streamline the production process, minimize errors, and save time and money by incorporating automated systems, machine learning algorithms, and other cutting-edge technologies.

Whether using sensors to detect product flaws before they leave the factory or optimizing workflow with real-time analytics, technology is changing the face of manufacturing in ways we couldn’t have imagined just a few years ago. As the industry continues to evolve, it will be exciting to see what innovations emerge and how they are utilized further to improve efficiency and accuracy in the production line.

Practical Tips and Best Practices for Innovative Supply Chain Management

Innovative supply chain management is about efficiency, effectiveness, and adaptability in an ever-changing landscape. To achieve this, practical tips and best practices are essential. From optimizing your inventory management to streamlining your transportation logistics, you can employ various strategies to stay ahead of the curve.

One critical approach is building solid partnerships with your suppliers and customers, which will help ensure all parties work towards common goals. Additionally, leveraging technology and data analytics can help you identify and respond to potential issues before they arise while providing further insights into improving your supply chain. By staying curious, collaborative, and grounded in best practices, you’ll be well-positioned to drive innovation and success in your supply chain management efforts.

Evaluating Cost vs. Quality Tradeoffs in Optimizing Your Supply Chain

When optimizing your supply chain, the age-old question of cost vs. quality inevitably arises. Do you prioritize having the lowest expenses or focus on ensuring the highest quality products and services? The answer depends on various factors, including your industry, customer preferences, and business goals. Evaluating the cost vs. quality tradeoffs can help you make informed decisions and strike a balance that best aligns with your business needs.

While reducing costs can increase your profit margins, it may also compromise your product’s quality and reliability, leading to dissatisfied customers and lost sales. Similarly, emphasizing quality may result in higher costs but can lead to better customer satisfaction and increased brand loyalty. Ultimately, the key is finding the sweet spot that provides the best value for your customers while supporting your business’s financial sustainability.

Conclusion

Christopher Linton says supply chain management in manufacturing is a complex system that requires immense experience and knowledge to navigate effectively. Its implementation can range from minimal to extensive, depending on the specific needs of your particular business. Understanding how to use it efficiently is essential for maximizing cost savings and potential quality gains.

We have discussed various strategies available to manufacturers, such as utilizing technology to increase efficiency, using best practices, and actively pursuing cost vs. quality tradeoffs. Successful supply chain management ultimately requires an informed decision-making process and an organized approach to integrating real improvements into the production line. With patience and dedication, supply chain management can help manufacturers create world-class operations that result in higher profits and expanded market opportunities.